Highly Instrumented Reactor for Atmospheric Chemistry (HIRAC)

HIRAC is a NERC funded facility designed to compliment the range of atmospheric chemistry related research being undertaken at the University of Leeds, in the form of field, laboratory and theoretical studies.

A detailed description of the design, setup and initial testing of the HIRAC chamber can be found here with a brief description of some of the important features provided below.

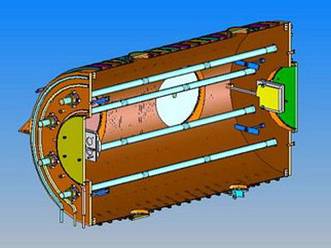

A solid works diagram of a cross-section through

A solid works diagram of a cross-section throughHIRAC showing the positions of the photolysis lamps.

A picture of HIRAC.

A picture of HIRAC.The design

HIRAC is a stainless steel cylinder with internal dimensions of 2.0 m long and 1.2 m diameter giving a total volume of ~2.25 m3. HIRAC was built with numerous mounting and access ports to allow a range of instrumentation, pumps, release valves, circulating fans and pressure and temperature measurement devices to be coupled to the chamber. Due to its strong stainless steel construction experiments can be carried out over a range of pressures of any desired bath gas up to 1 atm with the lower limit for the chamber pressure being determined by the specifications of the instrumentation required for a particular experiment. HIRAC can be pumped from atmospheric pressure to <0.003 mbar in ~60 mins using a rotary pump backed roots blower. This allows partial cleaning of the chamber between experimental runs. Thorough mixing of reaction mixtures is achieved by four low-vibration circulation fans mounted in pairs at each end of the chamber. Mixing times inside the chamber have been measured and are ≤ 70 s.

Radiation sources

Light for photochemical studies can be provided by several different types of lamps which have different spectral profiles and intensities in the UV region and are selected depending on the absorption spectrum of the photolabile species. The lamps, which are of two different lengths, are housed in eight quartz tubes mounted radially inside the reactive volume parallel to the chamber's principle axis. So far three different types of lamps have be used for experiments in HIRAC; Philips TLK40W/05 actinic UV blacklamps, GE G55T8 / OH 7G UVC lamps and Philips TL 40W/12 RS SLV UV-B medical therapy lamps. The output of the lamps is strongly temperature dependent outside of a narrow temperature range (~35-39°C) and so fans have been fitted at the ends of the quartz lamp housing tubes to force lab air through the tubes removing hot gases and regulating the temperature.

The homogeneity of the radiation profile within HIRAC is of particular importance where a homogeneous radiation field greatly simplifies the analysis and modelling of results of photolytic studies. Additionally the use of the FAGE instrument to measure OH and HO2 radicals (typically produced from photolytic sources) in HIRAC means that a homogeneous radiation profile is necessary to avoid radical gradients within the chamber. Through a combination of experimental, analytical and ray tracing results it has been shown that JNO2 is within ± 15% of the average for ~75% of HIRAC's volume. Additionally, measurements of OH across the chamber diameter showed that there is no significant radical gradient.

Temperature control

A picture of HIRAC after installation of the temperature control system.

A picture of HIRAC after installation of the temperature control system.HIRAC underwent the installation of a temperature control system in the summer of 2010 which allows variation of the temperature between 227 and 321 K. This is achieved by the circulation of 55 L of thermofluid (HUBE6479 DW-therm oil) from a high capacity thermoregulator (Huber Unistat 390W) through through series of stainless steel channels welded to the outside of the chamber body. The layout of these stainless steel channels provides an evenly distributed contact of thermofluid across the chamber outer surface and identical circulation pathway length for the thermofluid. The chamber is lagged in a double layer of 20 mm thick expanded neoprene which ensures a homogeneous temperature profile across the chamber. Temperature profiling of the chamber showed that the maximum difference in the measured temperature for d = 100 mm (where d is distance from the chamber walls) was ΔT = 0.3 K. Control of the temperature of the chamber will allow us to perform in depth mechanistic studies of atmospherically relevant reactions as well as to study reactions occurring in other planetary atmospheres due to our unique ability to simultaneously control the pressure of the chamber over a wide range.